Robots

Overview

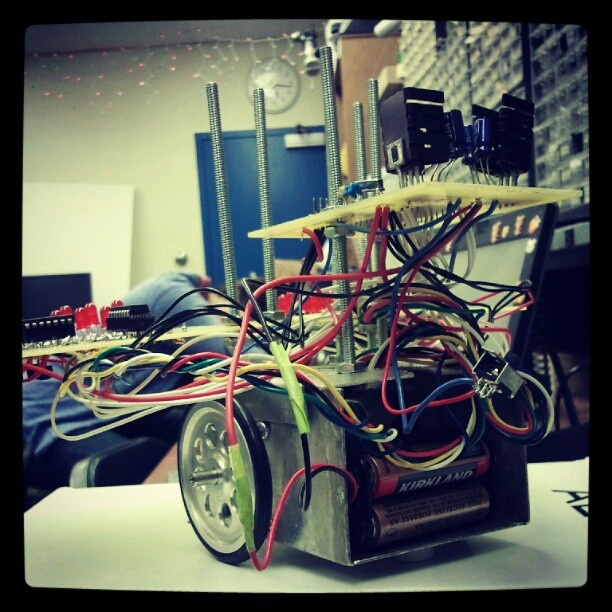

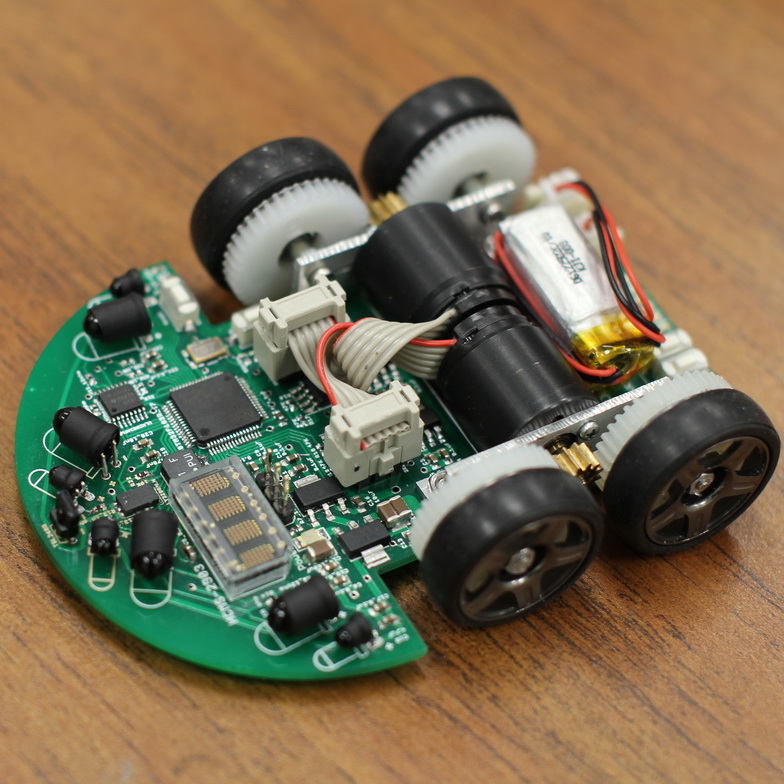

These are random robots i made through undergrad for either academic or recreational reasons.

’’’

X. Planetary Gear Robot

X.1: Overview and Robot Task

For 2.007 Design and Manufacturing I, several tasks are given for robots and students are free to design their robots to accomplish them. The robot is designed to turn a benzene ring with three attachment points at their centers (see picture.) comment: benzene ring pic

X.: Required Torque

Measuring the force using a spring scale and the distance from the center of rotation, the required torque was calculated at comment: pic

X.: Manufacturing

X.3: Testing

At first, the system was completely made of acrylic plastic. Taking a 0.25 inch plastic sheet and laser cutting it, the first set of gears was made. Material choice being acrylic plastic was due to the low friction the gears face as they grind against each other. comment: gear pics maybe w sheet too Then, testing the system, it works and exerts enough torque to turn. However, the sun and planet gears cracked with continious use, pointing to the need for less rigidity and more durable material. Aluminum was chosen due to its lightweight relative to other metals. As the rules dictated a maximum robot weight, this is important to keep in mind. Moreover, aluminum sheets are easy to cut and shape, so water jetting would not take too long. Friction between gears is still a concern as it lowers the amount of torque the system can output. Thus, testing the system to ensure at least [] N*m after this change is essential. comment: aluminum gears

X.4: Final Result

The system successfully turns the rings in an acceptable time window. comment: pic and vid?

X.Mini Me

X.1: Overview

This robot is design to push rock out of the way as part of MIT 2.007 robot designing curriculum.

X.2: Manufacturing

- Made from cardboard to test height and shape.

- Make base of robot

- Make attachment for pushing

- Ensure acceptable center of mass location to avoid tipping and sliding.